-

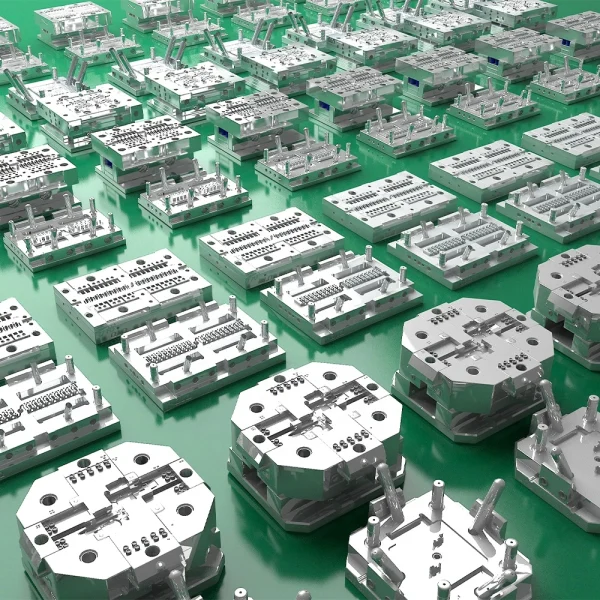

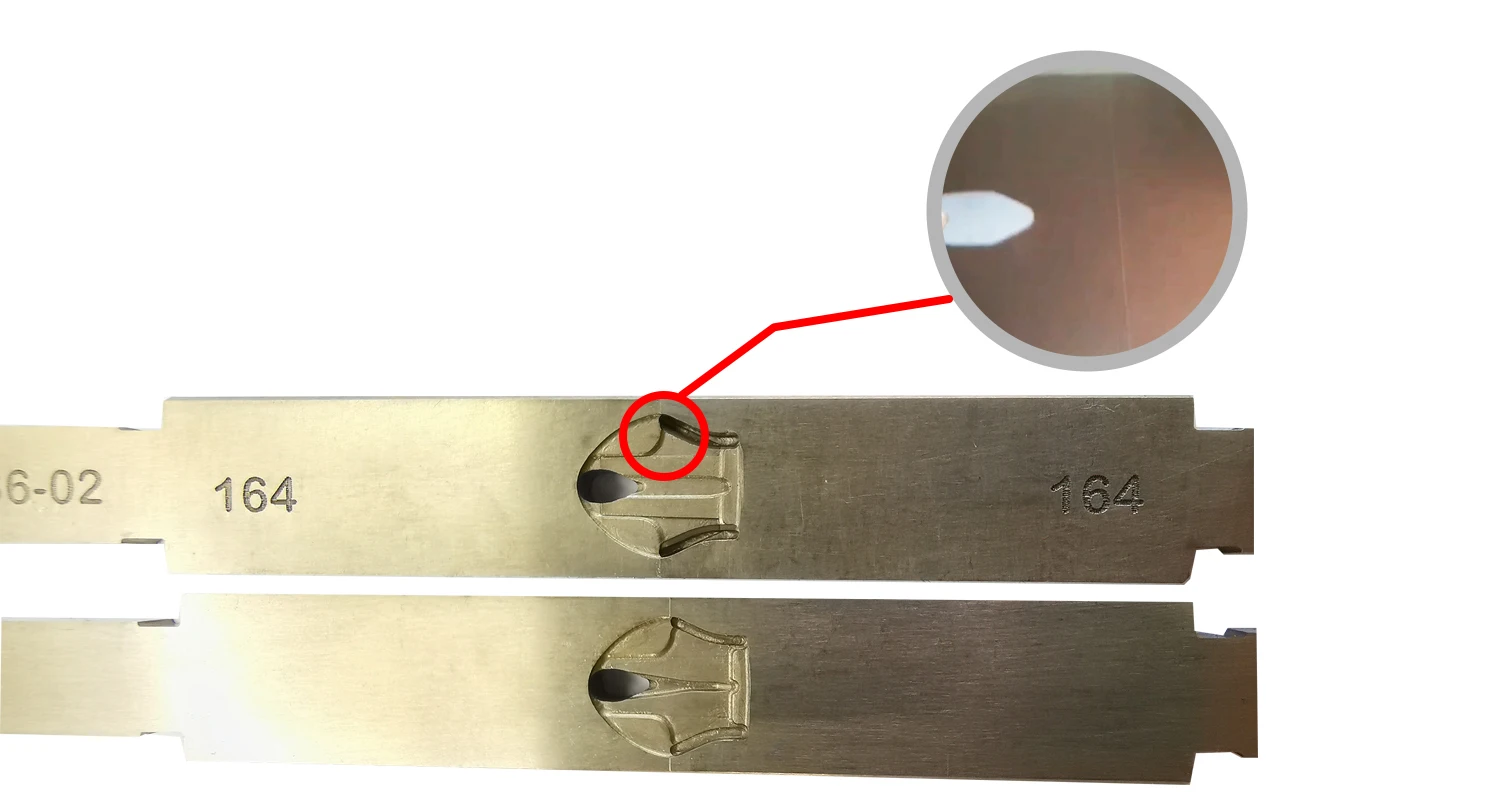

QLQ N36 Slider Body Mould Moving Core Zipper Slider Casting Moulds pressure die casting mould slider 10mm mold number 3

Key attributes

Other attributes

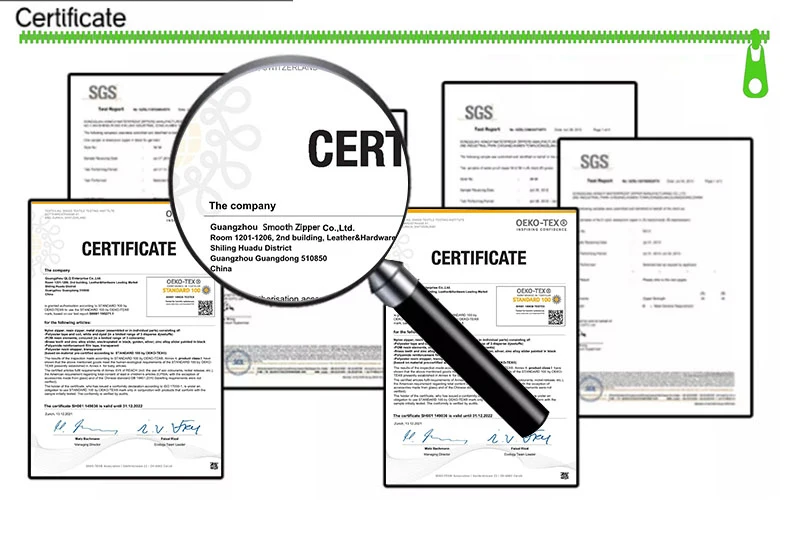

| Place of Origin | Guangdong, China |

| Brand Name | QLQ |

| Model Number | N36 |

| Product Material | FDAC, DAC |

| Product | zipper slider |

| Product type | Slider Mould Core |

| suitable products | slider die casting mould |

| material | DAC |

| weight | 25gram/pair |

Packaging and delivery

| Packaging Details | Standard export packing. |

| Port | Guangzhou |

| Selling Units: | Single item |

| Single package size: | 130X90X220 cm |

| Single gross weight: | 1000.000 kg |

Supply Ability

Supply Ability: 500 Set/Sets per Month slider mould core

Industry-specific attributes

|

Item

|

N36 non-lock slider body mould moving core

|

|

Material

|

Die steel, FDAC

|

|

Dimension

|

It's customized according to your mould.

|

|

Weight

|

around 30g/pair

|

|

MOQ

|

40 pairs

|

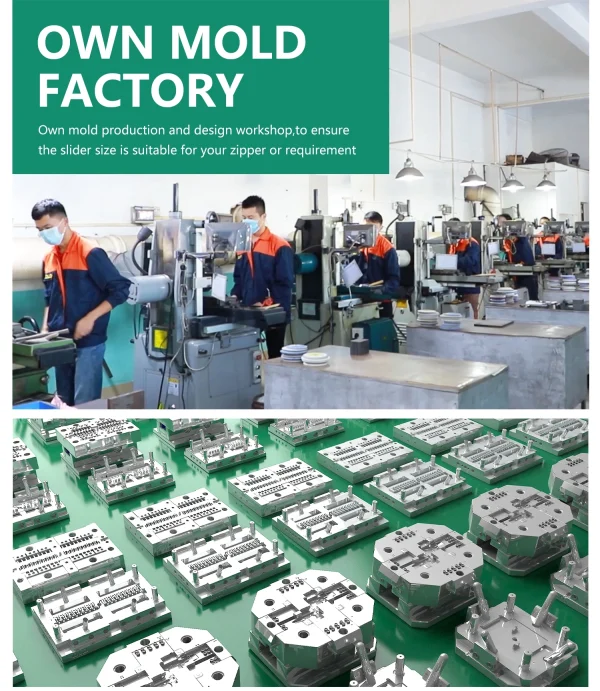

More than 20 years of mold design experience

Not only molds, but also machines

Please send us the drawing or the slider sample.

2. What is the tolerance of your moving cores?

In our mould factory, the grinding dimension tolerance of each mold core is 0.002 and the engraving dimension tolerance is 0.02, so that we can ensure that the product size does not have any serious size deviation

3. What is your moving core made of?

4. What is the advantages of your moving core?

Our moving core is of fine workmanship and precision. We chamfer the corners of the four sides to ensure that the moving core is more smooth when used on the mould and is not easy to get stuck.

5. What is the advantages of your die casting mould?

Related Products

-

QLQ-AMPM Automatic Mould Pressing Machine

QLQ-AMPM Automatic Mould Pressing Machine

-

Golden/Silver Film

Golden/Silver Film

-

Multi Colored Nylon Zipper 20# 3# 5# For Clothing Pants Bedding Talon Printed Strip Zipper No 5 Strings Universal Nylon Zipper

Multi Colored Nylon Zipper 20# 3# 5# For Clothing Pants Bedding Talon Printed Strip Zipper No 5 Strings Universal Nylon Zipper

-

Wholesale Metal Zipper Paint Metal Zipper With Aluminum Y Teeth For Handbag Garment Jeans Long Chain Metal Zipper

Wholesale Metal Zipper Paint Metal Zipper With Aluminum Y Teeth For Handbag Garment Jeans Long Chain Metal Zipper

-

Metal Teeth Nickel Zipper Tape Open End Aluminum Zipper Rolls For Handbag Concealed Zip Roll Long Chain Metal Zipper

Metal Teeth Nickel Zipper Tape Open End Aluminum Zipper Rolls For Handbag Concealed Zip Roll Long Chain Metal Zipper