-

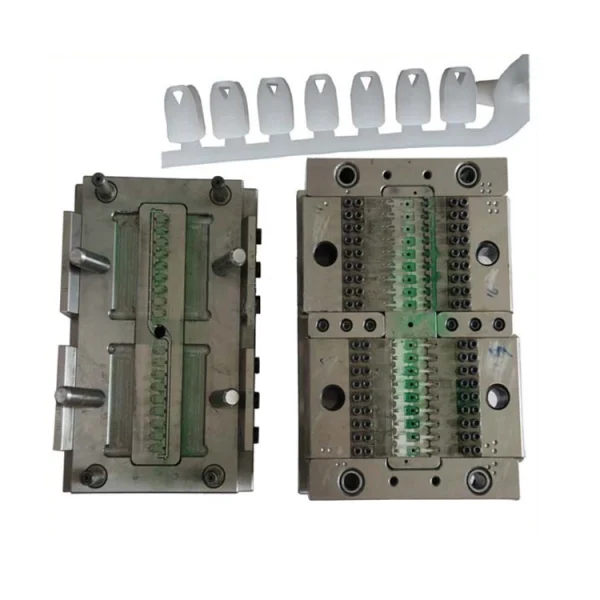

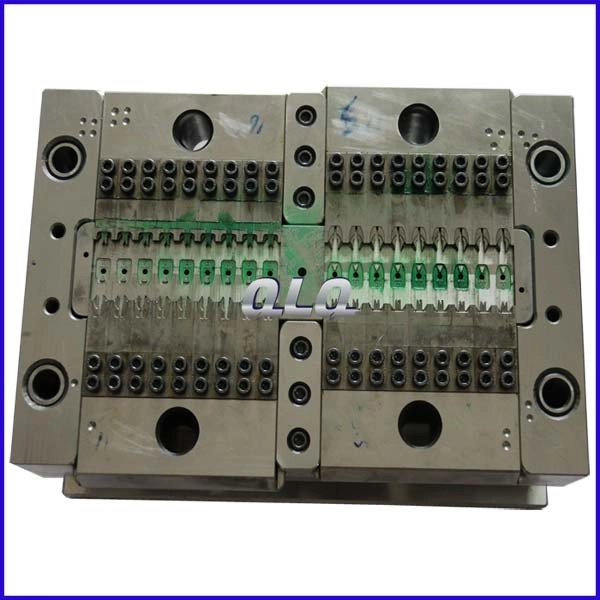

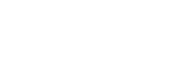

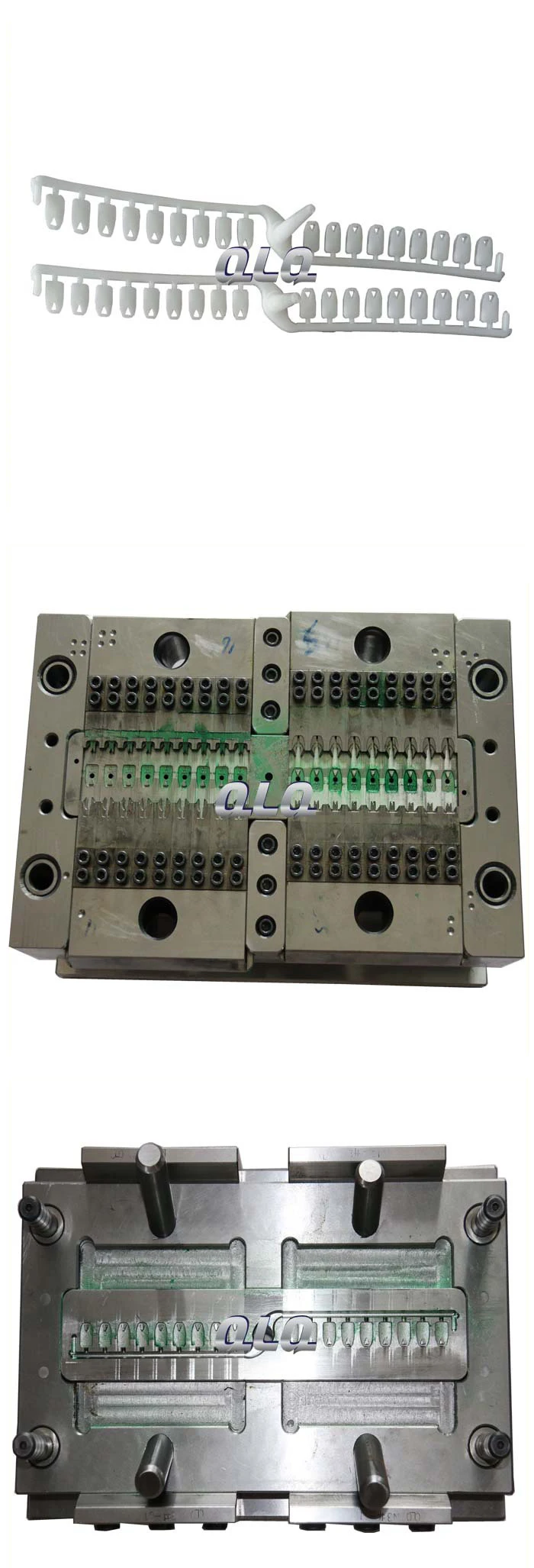

No.3# Slider Plastic Injection Mould for Nylon Vehicle Mould 100 Tons Slider Plastic Injection Machine Steel slider used mould

Key attributes

Industry-specific attributes

| Shaping Mode | Plastic Injection Mould |

Other attributes

| Place of Origin | Guangdong, China |

| Brand Name | QLQ |

| Model Number | N3 |

| Product Material | Steel |

| Product | Vehicle Mould |

| Product type | zipper slider plastic injection mould |

| available cavities | 18pcs or as per customer requirement |

| required machine | 100 tons slider plastic injection machine |

| products material | POM |

| required sample | 5-10 pcs plastic slider samples for plastic injection mould |

| suitable products | plastic slider for various kinds of zipper |

| injection mould packing | standard export wooden case packing |

Packaging and delivery

| Packaging Details | export standard wooden case for plastic injection mould |

| Port | Shenzhen |

Supply Ability

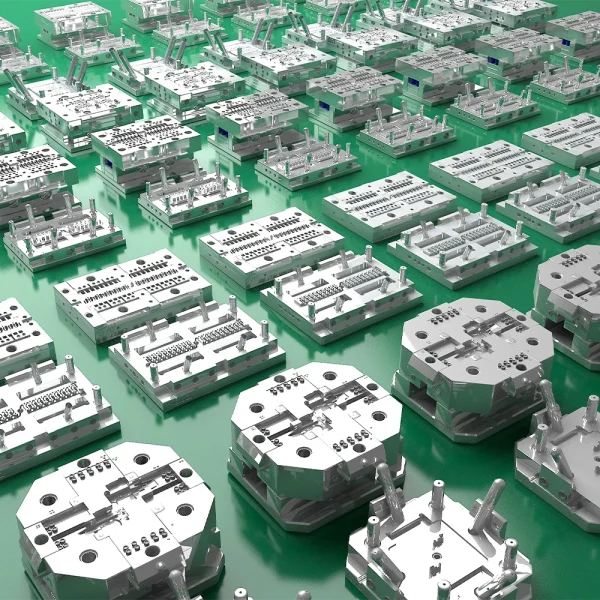

| Supply Ability | 30 Set/Sets per Month Injection mould |

No.3# slider plastic injection mould for nylon zipper

WE ARE THE DIRECT PLASTIC INJECTION MOULD MANUFACTURER

1-MOQ of slider plastic injection mould : MOQ 1 set mould.

2-Available material of plastic injection mould: same as the zinc die-casting mould the most important material is from original Japan Hitachi, Sweden ASSAB, or as per customers’ requirement.

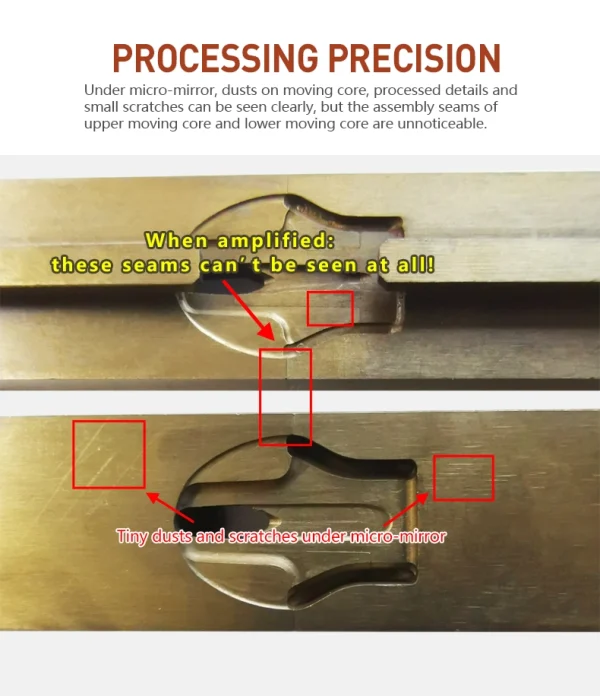

3-Workmanship: Heat treatment from original Hitachi factory. All workmanships are done by technicians who have more than 10 years experience.

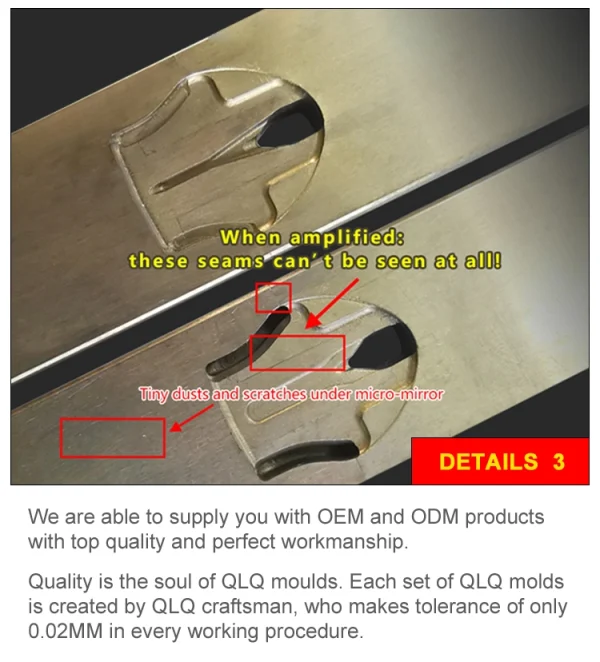

4-Accuracy: Drawings are made strictly as per sample or customers’ requirement and our engineer who have more than 25 years experience can give you professional advice once we found there is something need to be changed or improved for your slider samples for the plastic injection mould.Injection moulds will be strictly made as per drawing. And we required our technicians to make as less error as possible so that the moulds will run well and makes good products.

5-Inspection: We have complete quality inspection rules to make sure that all the plastic injection moulds are in good quality. We will check material before production, check processing and size during production, check product size and mould condition by testing slider mould after finishing production. We will test at least 500 shots for each plastic injection mould. And we will offer " Mould Inspection Report" after testing plastic injection mould.

6-After sale service: We will keep following up the slider injection mould condition after shipment. We will try our best and help customer to find the best solution. We are the strong technical support of our customers.

About our Factory workshop&Office

| It will be more reassuring to choose QLQ. QLQ has 21 years of experience in zipper industry service, and many large factories have cooperated with QLQ. | |

| QLQ has different technicians and often sends them to your factory for after-sales service. |