-

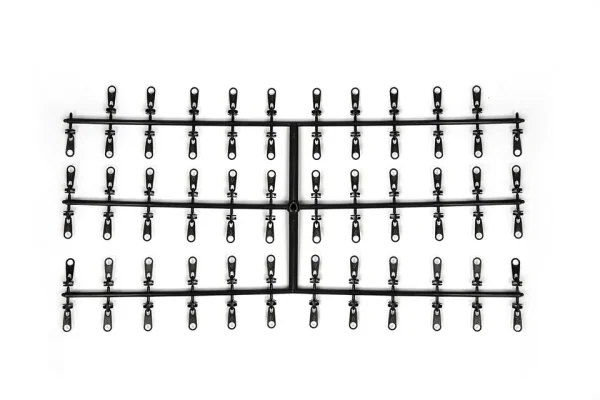

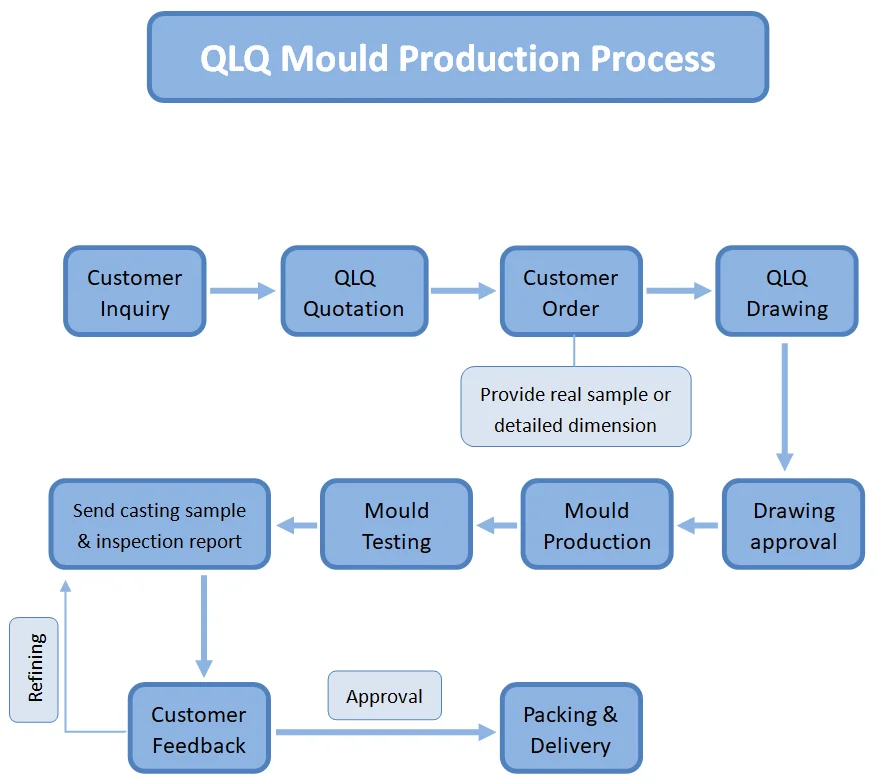

Injection Mould Zipper Slider Moulds Pom Plastic How to Make Plastic Slider Die Casting Steel N56 QLQ Plastic Slider Mould

Key attributes

Other attributes

| Place of Origin | Guangdong, China |

| Brand Name | QLQ |

| Model Number | N56 |

| Product Material | Steel |

| Product | zipper |

| Product type | Zipper Injection Mould |

| Application | QLQ die casting machine |

| Keyword | Plastic puller mould |

| Payment | 30% Deposit 70% Balance |

Packaging and delivery

| Packaging Details | export standard packing. |

| Port | Shenzhen |

| Selling Units: | Single item |

| Single package size: | 130X90X220 cm |

| Single gross weight: | 1000.000 kg |

Supply Ability

Supply Ability: 25 Set/Sets per Month

Industry-specific attributes

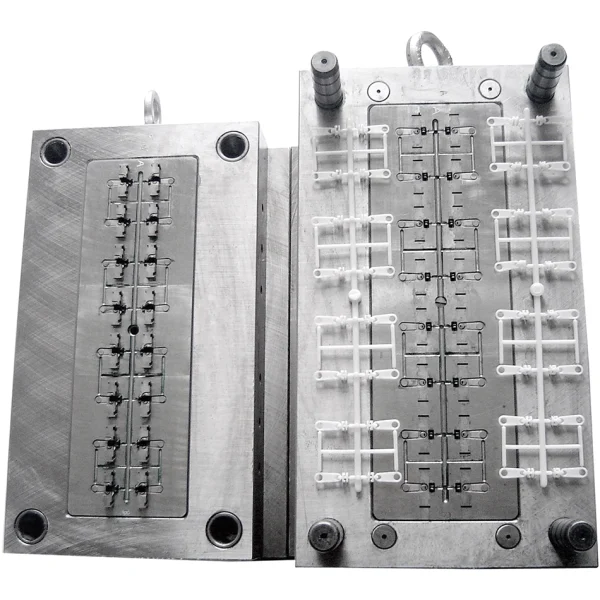

|

Item

|

Plastic slider injection mould

|

|

Cavities

|

32pcs/mould.

It's customized according to your injection machine and products.

|

|

Material

|

Die steel, LKM, ASSAB S136

|

|

Dimension

|

It's customized according to your injection machine and products.

|

|

Weight

|

around 500kgs

|

|

Service life

|

more than 1,000,000 moulds

|

|

Advantage

|

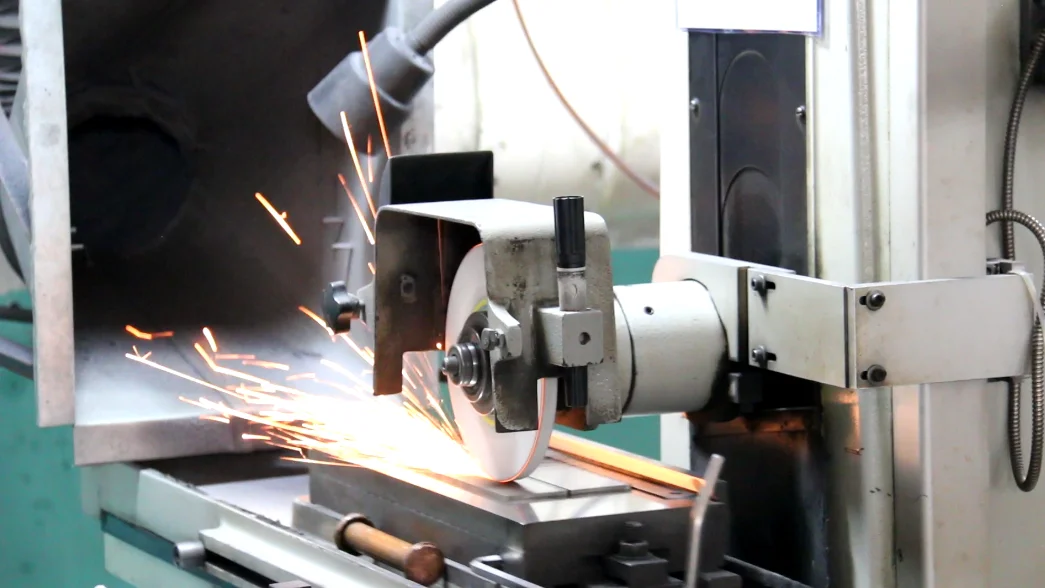

1. Our moulds are made by quality die steel material, LKM and ASSAB material.

2. With an experienced master team, which has been in the mould field for more than 15 years, we will design the mould according to your machine and required output, to improve your production capacity and keep the injection quality.

3. All the moulds will be tested until they are smooth opening and closing, to assure customers can use it directly under smooth situation when they receive moulds.

4. With precise moving cores, our moulds can make products without burr.

5. We can control the precision within 0.02mm.

|

QLQ: Yes, normally the spare parts for injection mould we have mould insert, mould frame, sliper, moving core, head of nozzle. You can check and inform what spare parts you need.

2.What is your mold frame made of?

QLQ: Our mold insert is made of LKM material.

3. What is your moving core made of?

QLQ: Our moving core is made of ASSAB S136 material.

4. What is the tolerance of your moving cores?

QLQ: The grinding dimension tolerance of each mold core is 0.02mm and the engraving dimension tolerance is 0.02mm, so that we can ensure that the product size does not have any serious size deviation.

Related Products

-

Stainless Steel Zip Roll Zipper Metallic Continuous For Bag Long Chain Brass Bag Pull Yard Zipper Tape Copper Coil Metal Zipper

Stainless Steel Zip Roll Zipper Metallic Continuous For Bag Long Chain Brass Bag Pull Yard Zipper Tape Copper Coil Metal Zipper

-

Single Twisted Centre Cord

Single Twisted Centre Cord

-

Double Twisted Centre Cord

Double Twisted Centre Cord

-

Metal Teeth Nickel Zipper Tape Open End Aluminum Zipper Rolls For Handbag Concealed Zip Roll Long Chain Metal Zipper

Metal Teeth Nickel Zipper Tape Open End Aluminum Zipper Rolls For Handbag Concealed Zip Roll Long Chain Metal Zipper

-

Golden/Silver Film

Golden/Silver Film